Go to the main page

by Bruce Mattson and Educational Innovations

The Gas Reaction Catalyst Tube is sold by Educational Innovations. The catalyst tube comes with a booklet of thirteen experiments and classroom demonstrations that can be performed in class or laboratory. Educational Innovations sells worldwide. Visit their website (Part Number GAS-100 or keyword 'gas') You can also look through the book that comes with the catalyst tube and read about the thirteen experiments and various gas tests.

CONTENTS

Part Two. Reactions Using the Catalyst

Part Three. Confirmatory Tests

Gas Reaction Catalyst Tube

PART ONE. GENERAL INFORMATION

The gas reaction catalyst tube that you have purchased consists of an extremely this coating of palladium atoms dispersed over a square tube shaped ceramic support. The palladium present is of almost negligible mass yet is the material that actually catalyses the reactions described here. The catalyst and ceramic support is housed in a 10-mm inside diameter tube (12-mm O.D.) made of borosilicate glass. The net volume of the glass tube is about 7 - 8 mL.

B. The Gas Reaction Catalyst Kit (Reorder Part Number GAS-100)

The gas reaction catalyst kit contains:

In addition to the equipment provided in the kit, you will need the following equipment in order to perform the catalytic reaction:

In addition, the various chemical tests of the gaseous products require equipment and chemicals that are not provided. These are described in the tests later in these instructions.

D. Setting Up the Apparatus

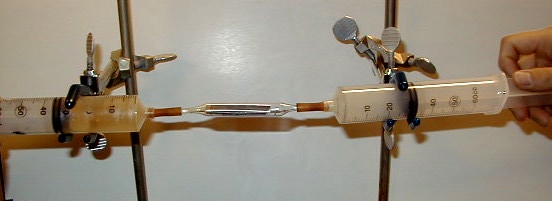

The assembled apparatus is shown in the Figure. Two short pieces (approx. 2-cm) of Latex tubing connect the catalyst tube to the two syringes. The syringe on the left contains the reagent gas mixture ready to be passed through the catalyst. The plunger of the receiver syringe (right) must be able to move freely in the syringe barrel because it should move outward on its own as the plunger of the reactant syringe is pushed inward. This is assured by lubricating the black rubber plunger diaphragm with silicone oil. Useful hint: Pull the plunger of the receiver syringe slightly outward so that the rubber diaphragm is not resting on the bottom of the barrel — this allows the initial outward movement of the plunger to commence at a lower positive pressure. Two ring stands and clamps hold the two syringes in the appropriate position above the burner's flame. The clamps should not hold the syringes tightly and must allow for free rotation of the syringes and catalyst tube for even heating. With some experience, we have found that it is easier to hold the syringes with one’s hands instead of using a ring stand.

E. Properly Heating the Catalyst Tube

Heat from a Bunsen burner flame is capable of softening the glass portion of the catalyst tube. When the glass is soft, it is susceptible to deformations and even "blow holes" if the pressure inside the system is increased by moving the plunger of the syringe. To prevent overheating the glass, use only a cool Bunsen burner flame. Minimize the amount of air used so that the flame has a soft, ill-defined blue inner cone. Position the catalyst tube at least 1 cm above the tip of the inner cone. Watch for traces of red, orange or yellow in the flame above the catalyst tube. These colors indicate that the glass is softening. If this should happen, remove the flame and adjust the flame.

F. Explosion Risk! Please Read!

The oxidation reactions involving hydrocarbons (methane and ethene) described herein utilize air as a source of oxygen. Do NOT attempt these catalysis reactions using oxygen instead of air! An explosion will result!

G. Activating the catalyst

The ceramic catalyst will appear tan or brown until it is activated. "Activation" simply involves heating the catalyst tube in a cool flame until it turns dark, sometimes even black. This takes less than a minute and can be done as part of the first experiment. Heat the catalyst tube evenly by rotating the syringes periodically in the flame.

H. Sources of Gases.

The gas catalysis experiments described here require samples of various gases. Compressed cylinders of gases are convenient and the purity is assumed to be quite good. Natural gas can be used as a source of methane. All of the reagent gases in this article can be prepared by simple methods we have described in our series in Chem13 News over the past several years. These gas preparations are also available in our book, Microscale Gas Chemistry, available from Educational Innovations and at our website (See Part Four). Gases prepared in this method contain small amounts of air.

by Bruce Mattson and Educational Innovations

The Gas Reaction Catalyst Tube is sold by Educational Innovations. The catalyst tube comes with a booklet of thirteen experiments and classroom demonstrations that can be performed in class or laboratory. Educational Innovations sells worldwide. Visit their website (Part Number GAS-100 or keyword 'gas') You can also look through the book that comes with the catalyst tube and read about the thirteen experiments and various gas tests.

CONTENTS

A. About the Catalyst

B. The Gas Reaction Catalyst Kit

C. Additional Equipment Required

D. Setting Up the Apparatus

E. Properly Heating the Catalyst Tube

F. Explosion Risk! Please Read!

G. Activating the catalyst

H. Sources of Gases

I. Toxicity

J. Clean-up and Storage

Part Two. Reactions Using the Catalyst

A. Oxidation of Methane with Air.

B. Oxidation of Ethene with Air.

C. Oxidation of Carbon Monoxide with Air.

D. Hydrogenation of Ethene

E. Catalytic Oxidation of Ammonia.

F. Methane and Nitrogen Dioxide.

G. Carbon Monoxide and Nitrogen Dioxide.

H. Decomposition of Nitrous Oxide

I. Nitrous Oxide and Ammonia

J. Nitrous Oxide and Carbon Monoxide

K. Nitrous Oxide and Methane

L. Trying Other Catalytic Reactions

Part Three. Confirmatory Tests

A. Acidity test.Part Four. Support

B. Ammmonia test

C. Bromine-water test.

D. Flammability test.

E. Gas chromatography.

F. Glowing Splint test

G. Limewater test

H. Water test

A. We repair and recycle!

B. Our Gas Chemistry Website

C. Microscale Gas Chemistry Book

D. Ordering syringes, parts, etc. from Educational Innovations

Gas Reaction Catalyst Tube

PART ONE. GENERAL INFORMATION

The gas reaction catalyst tube that you have purchased consists of an extremely this coating of palladium atoms dispersed over a square tube shaped ceramic support. The palladium present is of almost negligible mass yet is the material that actually catalyses the reactions described here. The catalyst and ceramic support is housed in a 10-mm inside diameter tube (12-mm O.D.) made of borosilicate glass. The net volume of the glass tube is about 7 - 8 mL.

B. The Gas Reaction Catalyst Kit (Reorder Part Number GAS-100)

The gas reaction catalyst kit contains:

• one catalyst tubeC. Additional Equipment Required

• two 60-mL syringes

• two latex LuerLOK syringe cap fittings

• one 17-cm length of latex connector tubing, 1/8-inch (3.175 mm) ID

• two plastic vial caps (used for generating various gases)

• this booklet

In addition to the equipment provided in the kit, you will need the following equipment in order to perform the catalytic reaction:

• a Bunsen burner

• two ring stands with one three-prong clamp each (optional)

• silicone oil lubricant

In addition, the various chemical tests of the gaseous products require equipment and chemicals that are not provided. These are described in the tests later in these instructions.

D. Setting Up the Apparatus

The assembled apparatus is shown in the Figure. Two short pieces (approx. 2-cm) of Latex tubing connect the catalyst tube to the two syringes. The syringe on the left contains the reagent gas mixture ready to be passed through the catalyst. The plunger of the receiver syringe (right) must be able to move freely in the syringe barrel because it should move outward on its own as the plunger of the reactant syringe is pushed inward. This is assured by lubricating the black rubber plunger diaphragm with silicone oil. Useful hint: Pull the plunger of the receiver syringe slightly outward so that the rubber diaphragm is not resting on the bottom of the barrel — this allows the initial outward movement of the plunger to commence at a lower positive pressure. Two ring stands and clamps hold the two syringes in the appropriate position above the burner's flame. The clamps should not hold the syringes tightly and must allow for free rotation of the syringes and catalyst tube for even heating. With some experience, we have found that it is easier to hold the syringes with one’s hands instead of using a ring stand.

E. Properly Heating the Catalyst Tube

Heat from a Bunsen burner flame is capable of softening the glass portion of the catalyst tube. When the glass is soft, it is susceptible to deformations and even "blow holes" if the pressure inside the system is increased by moving the plunger of the syringe. To prevent overheating the glass, use only a cool Bunsen burner flame. Minimize the amount of air used so that the flame has a soft, ill-defined blue inner cone. Position the catalyst tube at least 1 cm above the tip of the inner cone. Watch for traces of red, orange or yellow in the flame above the catalyst tube. These colors indicate that the glass is softening. If this should happen, remove the flame and adjust the flame.

F. Explosion Risk! Please Read!

The oxidation reactions involving hydrocarbons (methane and ethene) described herein utilize air as a source of oxygen. Do NOT attempt these catalysis reactions using oxygen instead of air! An explosion will result!

G. Activating the catalyst

The ceramic catalyst will appear tan or brown until it is activated. "Activation" simply involves heating the catalyst tube in a cool flame until it turns dark, sometimes even black. This takes less than a minute and can be done as part of the first experiment. Heat the catalyst tube evenly by rotating the syringes periodically in the flame.

H. Sources of Gases.

The gas catalysis experiments described here require samples of various gases. Compressed cylinders of gases are convenient and the purity is assumed to be quite good. Natural gas can be used as a source of methane. All of the reagent gases in this article can be prepared by simple methods we have described in our series in Chem13 News over the past several years. These gas preparations are also available in our book, Microscale Gas Chemistry, available from Educational Innovations and at our website (See Part Four). Gases prepared in this method contain small amounts of air.

Manipulating gases in syringes is generally safe and unintentional discharges are not common. Nevertheless, such discharges are possible and it is important to read and understand the following information. Nitrogen dioxide has an irritating odor and is a poisonous gas. Concentrations of 100 ppm are dangerous. To put this in perspective, if the contents of one entire syringe of NO2 (60 mL) were discharged into a volume of 1 m3, the concentration of NO2 would be 60 ppm. Ammonia has a pungent irritating odor and is highly poisonous. Although less toxic than ammonia and nitrogen dioxide, carbon monoxide is toxic but has no odor. Symptoms of carbon monoxide poisoning include headache, mental dullness, weakness, nausea and vomiting. Exercise caution when working with poisonous gases and vacate areas that are contaminated with unintentional discharges of gas.

J. Clean-up and Storage

After reactions, heat the catalyst for 30 seconds in the flame, remove the flame and purge the catalyst with a syringe filled with an inert gas such as nitrogen or argon. Air may be used if inert gases are not available. Allow the catalyst to cool. Store the gas reaction catalyst tube in a sealed plastic bag. Clean syringes with soap and water. Be sure to remove all of the lubricant as that will deteriorate the plunger’s rubber seal. To improve the syringe’s lifetime, store the plunger out of the barrel.

You may wish to perform one or more of the following tests, described in Part Three, on the reagent gas mixture and product gas mixture:

(a) Limewater test for CO2

(b) Flammability test

(c) Gas chromatography

(d) Water test

More information about this experiment along with pictures can be found at our gas chemistry website for methane. See Experiment 11 at this site.

B. Oxidation of Ethene with Air.

You may wish to perform one or more of the following tests, described in Part Three, on the reagent gas mixture and product gas mixture:

(a) Lime water test for CO2C. Oxidation of Carbon Monoxide with Air.

(b) Flammability test

(c) Gas chromatography

(d) Bromine-water test

(e) Water test

You may wish to perform one or more of the following tests, described in Part Three, on the reagent gas mixture and product gas mixture:

(a) Lime water test for CO2D. Hydrogenation of Ethene

(b) Gas chromatography

(c) If O2 is used rather than air, the Flammability and Glowing Splint test may be performed.

The Bromine-water test for C2H4 should confirm that there is less ethene in the product syringe than in the reactant syringe. Gas chromatography allows for a quantitative estimation of the extent of hydrogenation. See Part Three for details.

E. Catalytic Oxidation of Ammonia.

Fill the reagent syringe with 30 mL ammonia (1.2 mmol) and 30 mL oxygen (1.2 mmol.) In this proportion, NH3(g) is the limiting reagent. Connect the reagent and receiver syringes to the catalyst tube as shown in the Figure. For this reaction, do not pass any of the gas mixture through the catalyst tube to displace air from the tube. Heat the catalyst tube evenly on all sides for a total of about 30 seconds. Slowly pass about half of the ammonia/oxygen reagent gas mixture through the catalyst tube over the course of about 30 seconds. A cloud or fog of condensing water vapor should be noticed in the receiver syringe. After half of the gas mixture has been passed through the catalyst tube, remove the heat. Remove both syringes and cap them with Latex syringe caps. Label the syringes with a marker pen.

The relative amount of ammonia in each syringe is determined as follows. Note the volume of gas in each syringe. Remove the syringe cap and place each syringe in a 250 mL beaker filled with water. Draw at least 20 mL water into each syringe; ammonia will quickly dissolve. After a minute, note the new volume of the gas in the syringe. The product syringe will contain little or no ammonia, so the volume of gas will be about the same as its original value. The reactant syringe had contained 50% ammonia so that the volume of gas remaining should be half of its original amount. One may add some universal indicator to the discharged water from each syringe in order to estimate the pH. The unreacted ammonia will increase the pH substantially, while the product syringe may remain neutral. If nitric oxide were produced as occurs with the reactions described in the literature (see above), it would immediately react with oxygen present to form red NO2, an acid anhydride. Neither the red color of NO2, nor the low pH that a solution of the gas would produce is observed.

F. Methane and Nitrogen Dioxide.

In addition to detecting the reaction has taken place due to the disappearance of the red color, the product gases, described in Part Three, can be tested by the

(a) Limewater testThis reaction is highly suited for a lecture demonstration because the red color of the reactants can be seen to disappear while a fog of water forms in the product syringe.

(b) Water test

G. Carbon Monoxide and Nitrogen Dioxide.

In addition to detecting the reaction has taken place due to the disappearance of the red color, the product gases can be tested by the Limewater test, described in Part Three.

This reaction will take place without the catalyst present if high temperatures are used; this can be demonstrated by performing the reaction with a control (empty tube). The reaction requires a catalyst at lower temperature.

H. Decomposition of Nitrous Oxide

The thermal decomposition of nitrous oxide occurs above 300 oC. The reaction is:

Test the reagent gas mixture and product gas mixture by the following tests, described in Part Three:

(a) Glowing Splint test

(b) Gas Chromatography

I. Nitrous Oxide and Ammonia

Perform the tests, described in Part Three, on the on the reagent gas mixture and product gas mixture:

(a) Acidity testJ. Nitrous Oxide and Carbon Monoxide

(b) Ammonia test

(c) Water test

Perform the following tests, described in Part Three, on the reagent gas mixture and product gas mixture.

(a) LimewaterDo not perform the Glowing Splint test on unreacted N2O(g)/CO(g) mixture; this mixture of gases reacts explosively.

(b) Flammability

(c) Gas Chromatography

K. Nitrous Oxide and Methane

One or more of the following tests, described in Part Three, may be performed on the reagent gas mixture and product gas mixture:

(a) Limewater test for CO2

(b) Flammability test:

(c) Gas chromatography.

(d) Water test

L. Trying Other Catalytic Reactions.

Use caution when attempting other reactions with the catalyst tube. Explosive mixtures, even on the millimole scale are dangerous. When trying reactions for the first time, dilute the gas mixture with an inert gas such as argon or nitrogen. For example, NO2 and H2 react explosively unless diluted. The catalyst glows red and then the explosion occurs. In our case, the plunger shot out of the syringe, but the glass catalyst tube could have just as easily exploded. When new reactions are being explored, they should be done so with considerable dilution (perhaps 90% argon and 10% reagents) until the nature of the reaction has been worked out. Never use pure oxygen as an oxidant unless you have determined it is safe to do so. This is done by a series of experiments in which the amount of O2 is incrementally increased. We used this approach in working with Reactions C and E. Generally air can be used as ‘diluted oxygen;’ it is approximately 21% O2 and the rest is inert N2 and Ar.

PART THREE. CONFIRMATORY TESTS.

Prepare a universal indicator by dissolving 5 mL universal indicator in 50 mL distilled water. The concentration must be fairly high so that the colors are readily seen. Equip the syringe with a 15 cm length of latex tubing. Bubble 10 - 20 mL of the gas through the indicator solution. Remove the syringe and tubing. Notice color changes.

B. Ammmonia test

Ammonia can be detected by odor. Discharge 3-mL of the gas about 1-ft (30 cm) in front of your face. With a cupped hand, waft the gas towards your nose. Ammonia can also be detected by the Cu+2 test. Place 5 mL 0.10 M CuSO4 in a 15 x 180 mm test tube. Equip the syringe with a 15 cm length of latex tubing. Bubble 10 - 20 mL of the gas through the Cu+2 solution. Remove the syringe and tubing. Stopper the solution and shake to mix gaseous layer with Cu+2 solution. A deep blue solution indicates the presence of NH3 as a result of the reaction:

C. Bromine-water test.

Place 5 mL dilute bromine water (yellow, not orange) into a 15 x 180 mm test tube. Equip the syringe with a 15 cm length of latex tubing. Bubble 10 - 20 mL of the gas through the bromine water solution. Remove the syringe and tubing. Stopper the solution and shake to mix gaseous layer with bromine water solution. If alkenes are present, such as ethene, the yellow solution will turn colorless. The reaction is:

D. Flammability test.

Fill a small weighing boat with 3% dish soap solution. Equip the gas syringe with the 15-cm length of latex tubing. Discharge 10-mL gas into the soap solution in order to produce a mound of several large bubbles. Try to ignite the bubbles with a match. If the bubbles contain hydrocarbons, they may burn or pop rather than simply break. (Dish soap solution, 3%, is prepared by dissolving 3 g dish soap per 100 g water.)

E. Gas chromatography.

We use gas chromatography to separate and detect syringe gases. Our choice of column is a Porapak N 80/100, 6-ft (180 cm), inside diameter = 0.085 inches (2.2 mm), available from Alltech Part Number 2716; telephone: 847-948-8600. We use a thermoconductivity detector and run the GC at room temperature. Carrier gas is helium, 30-mL/minute.

F. Glowing Splint test

A traditional test for oxygen is the glowing splint test. Only one other common gas, N2O is capable of re-igniting a glowing splint. Connect the syringe to a glass pipet via a short length of latex tubing. Discharge 10 - 15 mL of the gas directly from the syringe onto the glowing splint. The discharge should be quick and as close to the glowing splint as possible. Pure O2 and N2O will re-ignite the splint into an open flame. Mixtures of these gases with other gases may prevent the splint from being re-ignited, however the splint will glow brightly while the gas is being discharged. In most cases, the splint will re-ignite, however.

G. Limewater test

Place 3 - 4 mL lime water in a 15 x 180 mm test tube. Equip the syringe with a 13 cm length of latex tubing. Discharge 10 - 20 mL of the gas above the surface of the limewater solution. Remove the syringe and tubing. Stopper the solution and shake to mix gaseous layer with limewater solution. A cloudy solution indicates the presence of CO2 as a result of the reaction:

H. Water test

When water is formed, the product syringe often appears 'cloudy' from the aerosol of water. After a few minutes, the aerosol condenses into minuscule drops of water lining the inside of the syringe. By pushing the plunger inward by 5 - 10 mL and then retracting it back outward by the same amount, the water droplets are pushed along ahead of the plunger. This greatly assists in seeing the droplets. As chemical confirmation, remove the plunger just long enough to add a piece of blue-colored Dririte (CoCl2 on an anhydrous CaCl2 granule) to the syringe. Return the plunger or stopper the syringe barrel. The presence of water is confirmed if the blue granule turns pink-purple within a few minutes.

B. Our Gas Chemistry Website

We have published 16 articles in Chem 13 News (with several more on the way!) describing the microscale preparation and experimentation for a wide variety of gases. All of these articles are available on our gas chemistry website or in our book on microscale gas chemistry experiments which is at:

C. Microscale Gas Chemistry Book

Own your own copy of all of the microscale gas chemistry experiments published in our Chem 13 News series. The book includes a detailed index, ordering information and information about each gas. Spiral bound, 270+ pages. Sold exclusively by Educational Innovations, Item #BK-590, $29.95.

D. Ordering syringes, parts, etc. from Educational Innovations

• gas reaction catalyst tube only (Item # GAS-120)

• syringes, 60-mL plastic syringe with a LuerLOK fitting (Item # GAS-140)

• syringe cap fittings, latex LuerLOK (Item # GAS-160)

• plastic vial caps (Item # GAS-180)

• latex tubing, 1/8-inch (3.175 mm) ID, 5 ft (1.75 m) lengths (Item # GAS-220)

• metal locking hemostat (Item # GAS-200)

JC standing by her St Albert's Day poster, Creighton University, November 11, 2002

No comments:

Post a Comment